Identifying mycotoxins is important.

Growing conditions during the crop year often leave cattle feeders and nutritionists concerned for mold and yeast growth on corn and other grains throughout most of the Corn belt. The 2020 growing and harvest season seemed to be an improvement over the last three years, but there are still pockets of the region that are experiencing challenges with mycotoxins. Simply observing mold on corn does not mean that mycotoxins are present. A first but important step is to identify the main types of molds and yeast present. Identification of the potential mycotoxins in the feed is important when formulating a plan for minimizing the effects on cattle.

The Premier Cooperative Nutritionists have a long list of options available to help diagnose potential production robbing challenges. One of the vendors we work closely with is PMI (Performance Minded Ingredients). PMI is supported with Act Lab toxin testing services at no cost to the Co-op or Producer. Act Labs provides high sensitivity test to determine all major toxins that impact animal performance. PMI has developed a step by step guide to bring awareness to producers from an educational standpoint.

All of our Premier Nutrition Consultants have access to PMI’s labs and offer these services which can help determine appropriate response to feed challenges along with supporting the health and immune function of cows. Not only can PMI run a very high quantified panel on toxins we can also add mold and yeast counts to the testing regime. PMI’s Dairy approach gives the dairy producer and feed consultant an approach that creates a clear solution front to back from mitigating the issues to adding necessary gut products such as live yeast, fiber digesting enzymes and complete DFM packages. With any of these, proper placement of products is key to establishing a balance back into the herd.

Any challenge is never one single step and that is demonstrated with all commercially available products in the market today when it comes to mycotoxins. We can help mitigate the challenges. Understanding the source and the challenge allows us to have a complete program that returns performance back to where it was.

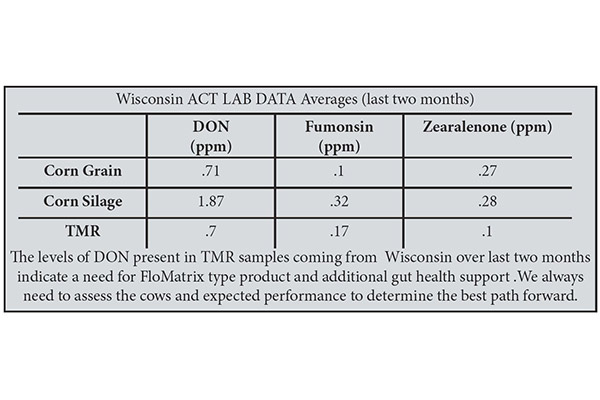

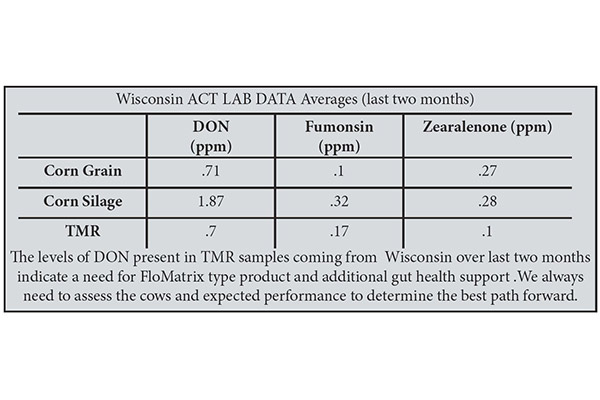

Wisconsin ACT LAB DATA Averages over last two months looks like the below table.

Contact your Premier Nutrition consultant to help identify if there is a risk factor in the corn or corn silage and develop a strategy to minimize the potential risk.

Joe McDonald

Nutrition Consultant