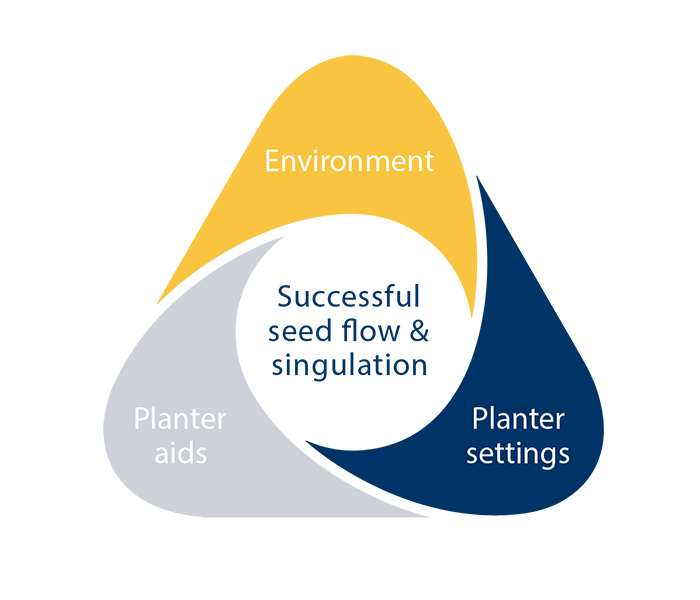

Best practices to improve seed flow and singulation.

Several factors, such as air and seed temperature, relative humidity, seed treatment recipe, as well as seed size and shape impact seed flow and plantability.

Excellent planting accuracy and plant stand establishment can be achieved with all seed sizes and shapes, regardless of seed treatment recipe and environmental conditions, through careful planter aid usage and planter adjustments.

This guide highlights environmental conditions that result in challenging planting conditions, as well as best practices to optimize planting accuracy.

The challenge: Spring weather is unpredictable

Warming spring temperatures signal the beginning of the crop planting season. However, weather in spring is unpredictable with cold, dry conditions often followed closely by warm, humid conditions. Rapid fluctuations in weather can create condensation on the seed, causing poor seed flow, increased seed bridging and reduced planter accuracy.

For example, when seed is stored at 50°F, condensation can start to occur as soon as the seed is moved into warmer, more humid conditions common during the Spring planting season. When condensation accumulates on seed, planting accuracy can be impacted if not managed properly.

The opportunity: Be prepared for Spring weather

- Planter aids: diligently and thoroughly apply planter aids as recommended by your planter manufacturer. Data has shown that priming the planter unit with graphite or a talc/graphite blend, as well as mixing the planter aid properly with the seed, can greatly improve seed flow and singulation.

- TALC: a naturally occurring mineral that acts as a drying agent, while reducing static electricity.

- GRAPHITE: a crystalline carbon lubricant that helps reduce equipment wear, improves seed flow and reduces static electricity. Not a drying agent.

- FLUENCY AGENT: a polyethylene wax-based lubricant used to aid seed flow. Not a drying agent.

- Contact your local ag retailer or Brevant® seeds retail product agronomist for precise recommendations on planter settings, and access batch-specific information for individual planters. Adjust settings to planting conditions following manufacturer instructions.

- Environment: slowly increase seed storage temperature and provide increased air flow to minimize seed condensation. When using boxes or large pallets of seed bags, warming the seed should be done over numerous days (ideally, 1-2 weeks) if feasible.

Contact your local Premier agronomist for more information and precise planter recommendations