Rootworm Control for 2021.

2020 certainly had challenges. Wind, a dry spell in August, depressed commodity prices, COVID, Rootworms.

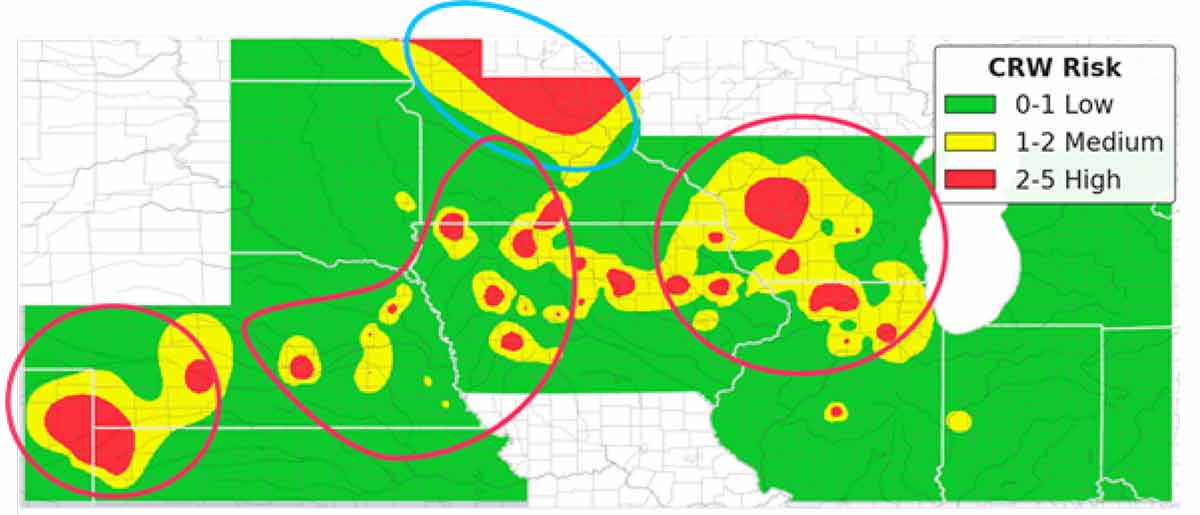

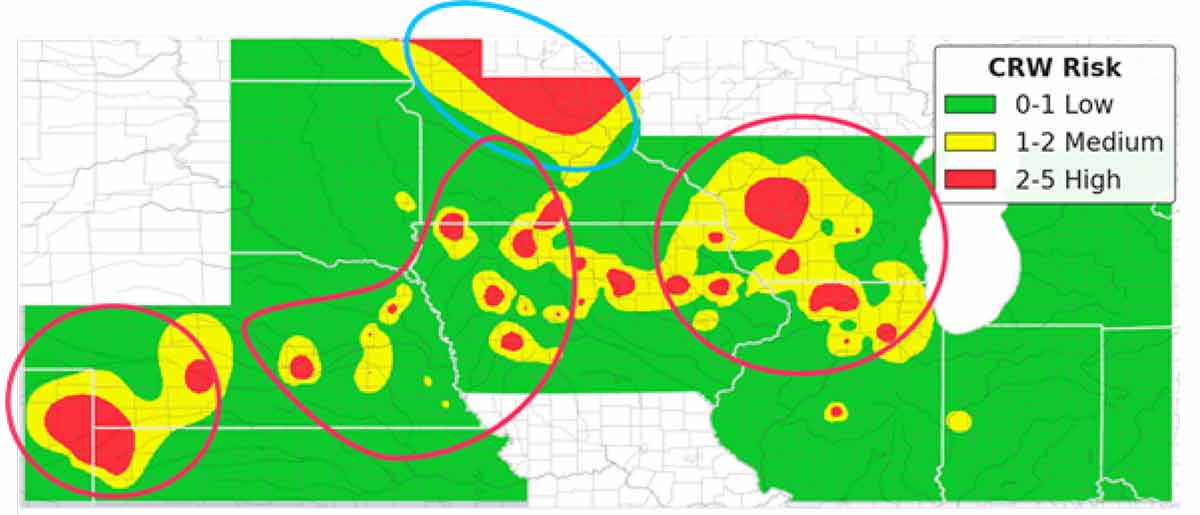

Yes. Rootworms. The populations of our despicable perennial pest of Continuous Corn are back and predicted to be stronger than in 2020, according to a risk assessment study conducted by Bayer CropScience in 2019 and 2020. Bayer’s analysis of 1440 fields across a 12 State area showed the continued enlargement of rootworm “hot spots” across Eastern Iowa, Northern Illinois, and Southwest Wisconsin. Their data essentially places the entirety of the Premier Cooperative trade area into a Moderate Risk or High Risk category for damaging populations of corn rootworm in 2021.

Figure 4a. Estimated corn rootworm risk in 2020 using interpolated 2019 corn rootworm counts from corn fields sampled (based on 1123 fields). 2020 Research Report ©2020 Bayer Group

To further complicate matters, the EPA has now confirmed resistance in Southwest Wisconsin to the “Herculex” corn rootworm trait. This means that as of today, there is some level of resistance to all commercially available Bt rootworm control options. That is not to say that resistance is guaranteed in any given area, but there is a risk.

During the 2020 growing season, across much of Wisconsin, we endured several abnormally strong wind events. Although this did not affect every producer equally, it caused us to take a closer look at the root systems of our corn than we had in years. In some cases we found nothing wrong; in other cases we found a tremendous amount of compaction, and in other cases we found multiple nodes of rootworm feeding.

Damaged roots are always a problem and always hurt yield. However, the cause of the feeding is not always resistance. It can also be what I call “overwhelming pressure”. In Bt corn, rootworm larvae always need to feed in order to ingest the Bt protein that is to control them. A million larvae = a million bites. They will still eat a lot of root material before we get control.

So, resistance or not, our need to control rootworm in the face of heavy pressure may require extra attention in 2021. The good news is, we have many effective insecticide options that we can utilize for various corn planter configurations.

Historically, a dry granular insecticide such as Force or Aztec would be our go-to for heavy duty control. It is likely the simplest product to use overall. The only drawback is that a planter needs to have special dry application boxes equipped in order to apply this type of product. This may limit it’s use with new planters.

If dry application equipment is not available, there are effective liquid options as well. Force EVO and Index Liquid have both shown to be very effective choices, although they need to be injected downstream of a liquid starter tank. It is a pretty minimal amount of additional injection equipment, and would be more likely to work on a newer planter with an in furrow starter system.

What about tank-mixing with liquid starter? Products like Capture LFR or Ethos XB are both labeled to be directly mixed with liquid starter and are less costly than other rootworm products. However, they are not going to give the same level of control that you would expect with other rootworm insecticides, and there is some evidence of field evolved resistance to the active ingredient in these products.

In summary, consider the value of the upcoming corn crop to the cost of additional rootworm control to see if the economics make sense on your farm. Remember, in addition to control of rootworms, all soil applied insecticides provide some level of secondary pest control. Better plant stands and less root pruning will always lend itself to higher yields, even if corn rootworm pressure is less than expected. Consider rootworm control as part of your overall risk management strategy for 2021.

Dan West

Crop Production Specialist